For industrial automation, with the improvement of productivity and the demand for cost reduction and efficiency improvement, the trend of industrial enterprises to set up automated production lines and create intelligent production workshops is becoming more and more obvious. In the production process, LiDAR can assist in material monitoring on the conveying equipment. The Lidar is installed in the middle of the beam of the support frame, and the Lidar quickly scans the materials on the conveyor belt when measuring, and transmits the scanning data and the speed and width of the conveyor belt to the computer, which can effectively ensure the smooth process flow on the conveyor belt.

AGV/AMR is also an industry with more liDAR applications. The use of LiDAR assisted navigation can make the AGV car travel along the specified path, while providing safety protection and a variety of load shifting functions. At present, there are two main types of liDAR used by mobile robots: one is the navigation radar, which is responsible for the path planning and guidance of AGV; The second is the obstacle avoidance radar, which is responsible for the safety protection of the AGV traveling area.

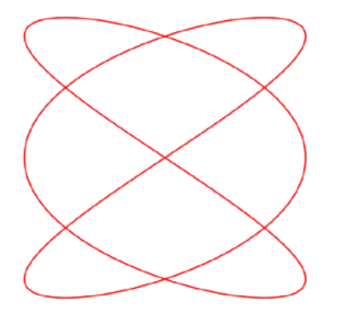

In the application of MEMS micromirrors in industrial Lidar, there are two laser scanning methods, inSync MMA technology uses raster scanning, and you can contact the company's technical support team for specific use.

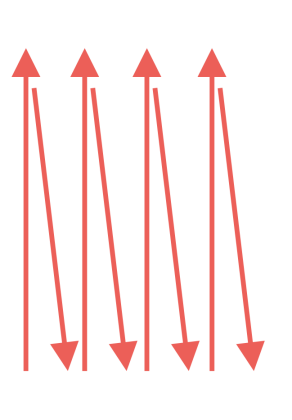

Raster Scanning (2D Hybrid Mode)

Refresh rate: 2KHz (Vertical)/10Hz(horizontal)

Raster Scanning (2D Hybrid Mode)

Refresh rate: 2KHz (Vertical)/10Hz(horizontal)

Smart logistics is also one of the most applied Lidar industries, covering the whole process from handling to warehousing, and even covering port logistics and other fields. In terms of smart storage, LiDAR can assist the stacker to realize the automatic entry and exit of goods. The piler is equipped with liDAR, which can ensure accurate obstacle avoidance when the piler moves, and can also be used to assist in positioning. This type of three-dimensional intelligent storage based on stackers has been widely used in various manufacturing scenarios, especially in the lithium battery industry.

In addition, regarding the interactive operation of container grab, how to carry out fully automated interactive operation safely and efficiently when the rail crane grabs the container from the collection truck on the dock or shelf is an industry problem that has not been solved in the world's ports, because once the lock pin of the container and the trailer of the collection truck is not completely separated, it is easy to cause the collection card to be lifted during the unloading of the rail crane. There are great security risks. With the positioning technology of intelligent Lidar and image recognition, manual intervention is avoided, the safety of the operation is further improved, and the industry problems are effectively solved.

inSync is a MEMS enterprise engaged in R&D, manufacturing and application of automotive/Industry/Consumer/Medical. The company is dedicated focus in MEMS actuators, devices, sensors, and application system

Details备案号码:沪ICP备2023016714号